ADEKA for roofing

- Roofing

- Screws

- Hidden

- Overlapping

- ADEKA

- Aesthetic of diamond shaped

- Fast and easy installation making it a cost effective solution

- Small preformed elements

General information

ADEKA is an innovative patented facade system based on small pre-formed QUARTZ-ZINC or ANTHRA-ZINC elements featuring a unique locking key (other finishes on request).

ADEKA can be fixed to both vented open gap softwood boards and vented 3/4" plywood with VMZINC Membrane.

Areas of application

Suitable for both renovation projects and new buildings.

All types of buildings: commercial, public buildings, collective and individual housing

Technical data

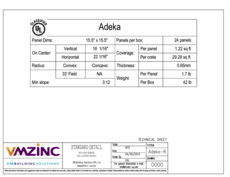

| Material Thickness | 0.65mm (0.0256") |

| Panel Dimensions | 15.5" x 15.5" (393.7mm x 393.7mm) |

| On Center | Vertical 16 1/16" (408mm) Horizontal 22 1/16" (560mm) |

Coverage per Panel | 1.22 SF |

| Panels per Box | 24 panels |

| Coverage per Box | 29.28 SF |

| Weight per Panel | 1.7 lbs |

| Weight per Box | 42 lbs |

| Minimum Slope | 3:12 (14.04⁰ or 25%) |

Finishes

See all aspects-

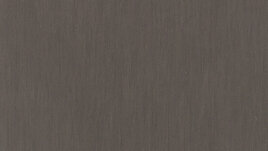

ANTHRA-ZINC

ANTHRA-ZINC -

AZENGAR

AZENGAR -

PIGMENTO Blue

PIGMENTO Blue -

PIGMENTO Brown

PIGMENTO Brown -

PIGMENTO Green

PIGMENTO Green -

PIGMENTO Red

PIGMENTO Red -

QUARTZ-ZINC

QUARTZ-ZINC

Documents and drawings

Please enter your E-mail address. We will send you the download link by mail.

Installation

See all our installation videosDescription

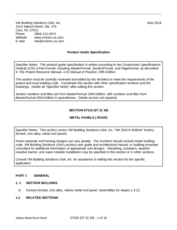

The panels are installed from bottom up with the key fixing into the lower panel.

Each ADEKA tile is then secured with 3 screws. ADEKA is not supplied with filmed VMZINC. Roofing shingles (flat lock panels) can also be installed on a roof in a similar fashion to the ADEKA tile however the minimum slope for the majority of projects using diamond shingles with non-aligned joints is 45 degrees.