Interlocking panel

- Facade

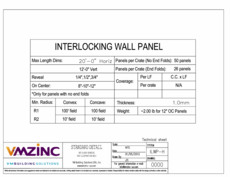

- Clips

- Hidden

- Reveal

- Interlocking panel

- Elegant linear panels

- Variable joint size

- Vertical and horizontal installation

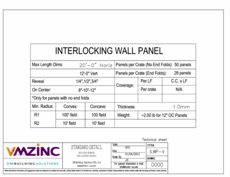

General information

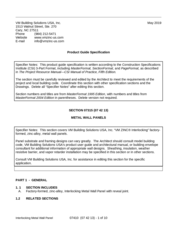

Interlocking Panels consist of a panel face, reveal joint and are fixed in position using hidden fasteners. The panels can be orientated horizontally or vertically and can be applied equally to soffits. Panels are available in all finishes of 1mm thick VMZINC with standard panel widths being 8", 10", and 12". Joint widths can be 1/4", 1/2" or 3/4". It should be noted that panel width = panel face + joint. The depth of the panel is 1".

Areas of application

Suitable for both renovation projects and new buildings.

All types of buildings: commercial, public buildings, collective and individual housing

Technical data

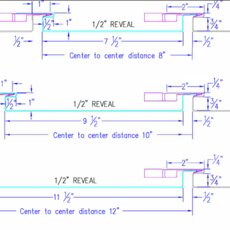

| Panel Depth | 1" (25mm) |

| Maximum Dimensions | Horizontal 20'-0" Length (6.09m) Vertical 12'-0" Length (3.65m) |

| Minimum Dimensions | 30" (762mm) with End Folds 24" (609mm) without End Folds |

| Coverage Dimensions | 12" (304mm) OC, 10" (254mm) OC, 8" (203mm) OC |

| Reveal Dimensions | 1/4" (6mm), 1/2" (12mm), 3/4" (19mm) |

| Weight | ~2.0 lbs per SF |

Finishes

See all aspects-

ANTHRA-ZINC

ANTHRA-ZINC -

AZENGAR

AZENGAR -

PIGMENTO Blue

PIGMENTO Blue -

PIGMENTO Brown

PIGMENTO Brown -

PIGMENTO Green

PIGMENTO Green -

PIGMENTO Red

PIGMENTO Red -

QUARTZ-ZINC

QUARTZ-ZINC -

Natural zinc

Natural zinc

Documents and drawings

Please enter your E-mail address. We will send you the download link by mail.

Installation

See all our installation videosDescription

The panels are installed in a sequential order from top to bottom for horizontal panels. The upper edge of each panel is engaged into the lower edge of the panel above. The panels are mechanically attached using screws and/or the panel fixing clip that allows for thermal movement. The panels should be installed with the protective film in place. Protective film is recommended to be removed within 60 days post installation.