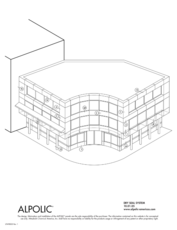

ALPOLIC Zinc Composite panels

- Facade

- Screws

- Hidden

- Reveal

- Composite

- Panels with large dimensions

- Exceptional smoothness and rigidity

- Solutions for complex shapes thanks to an excellent aptitude for transforming and bending

General information

The allure of zinc has captivated architecture for centuries. ALPOLIC® is proud to offer zinc composite materials (ZCM) for elegant facades with all the quality and versatility ALPOLIC MCM is known for.

The robust natural metal is now available in a variety of hues that further accentuate the distinct natural grain texture of zinc.

When installed in the right environment, the naturally occurring patina process of zinc can form a protective layer, creating a long-lasting corrosion resistantance.

Areas of application

Suitable for both renovation projects and new buildings.

All types of buildings: commercial, public buildings, collective and individual housing

Technical data

Standard sheet size |

|---|

| 38" x 146" (965mm x 3,708mm) |

Finishes

See all aspects-

ANTHRA-ZINC

ANTHRA-ZINC -

AZENGAR

AZENGAR -

PIGMENTO Blue

PIGMENTO Blue -

PIGMENTO Brown

PIGMENTO Brown -

PIGMENTO Green

PIGMENTO Green -

PIGMENTO Red

PIGMENTO Red -

QUARTZ-ZINC

QUARTZ-ZINC

Documents and drawings

Please enter your E-mail address. We will send you the download link by mail.

Installation

See all our installation videosDescription

ALPOLIC® material is trimmed and squared with cut edges.

Sheets should be stored flat in a dry, indoor environment.

Zinc should only be installed using a rain screen system.

ALPOLIC® and VMZINC recommend the use the same metal on both sides of composite material in order to avoid sheet distortion caused by the differing rates of thermal expansion of dissimilar metals.

The panels should be installed with the protective film in place. Protective film is recommended to be removed within 60 days post installation.